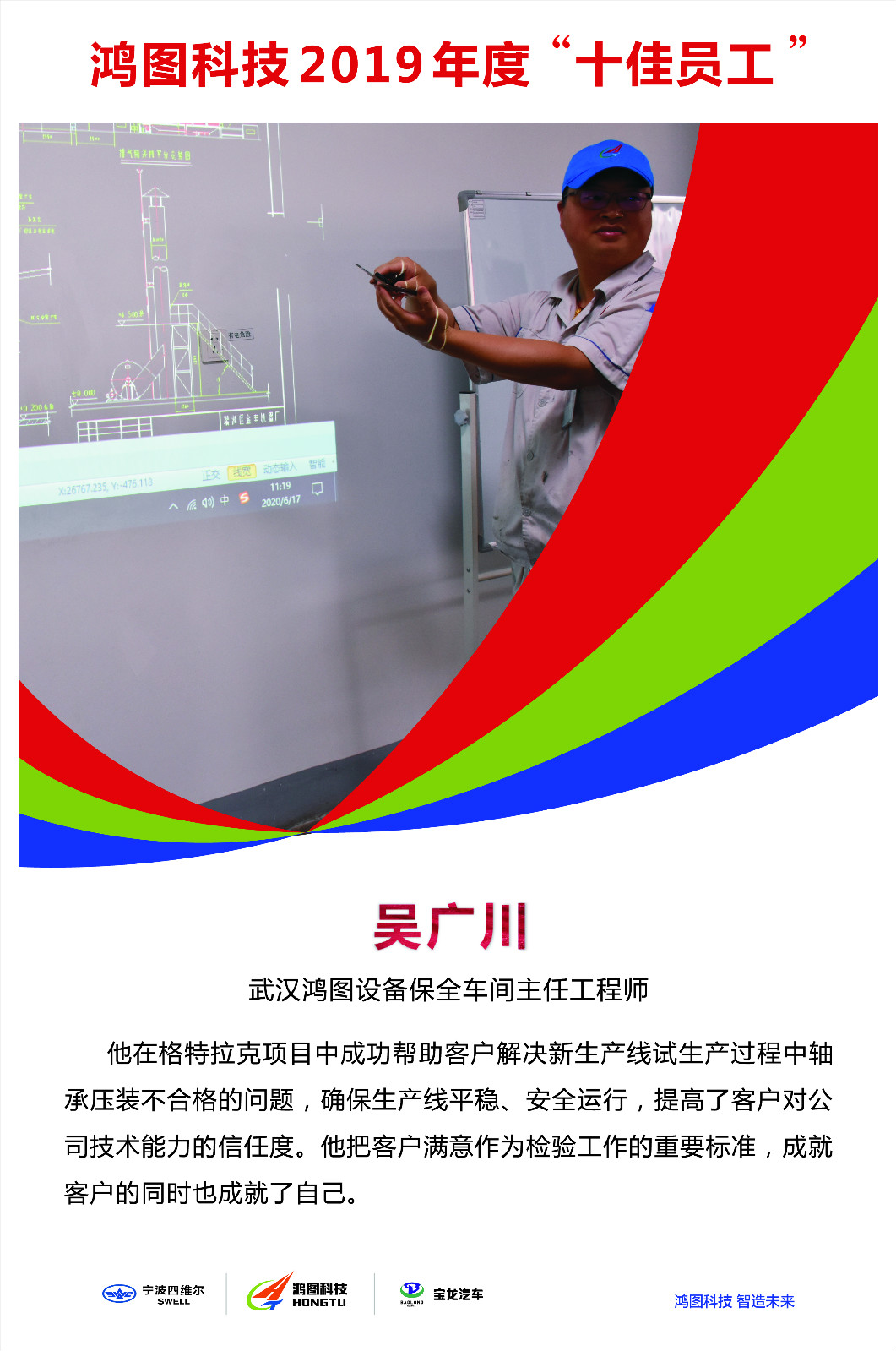

As the chief engineer of Wuhan Hongtu Equipment Preservation Workshop, Wu Guangchuan is mainly engaged in technical improvement and key problem tackling of special mechanical equipment and fixture. He has successively worked as a CNC equipment engineer and chief engineer since he took work. He has always adhered to the customer-oriented core value, and continued to create values for the company.

As the chief engineer of Wuhan Hongtu Equipment Preservation Workshop, Wu Guangchuan is mainly engaged in technical improvement and key problem tackling of special mechanical equipment and fixture. He has successively worked as a CNC equipment engineer and chief engineer since he took work. He has always adhered to the customer-oriented core value, and continued to create values for the company.With rich theoretical support, clear chart description and accurate experimental data, he has meticulously answered GM's consulting questions about screw plug tightening technology, and Honda's technical questions on the principle of radial motion riveting, obtaining the customers’ high recognition.

He assisted Gertrag customers to solve the problem of DCT300 bearing assembly line, actively explored to break through technical difficulties, tackled difficult problems and developed solutions, ensured the production line to run without trouble, which further consolidated the customers’ confidence in the technical ability of the company.

He independently designed the fixture tray, which refined the log foot tray into the double gauge iron anti-slip tray, increasing the safety of the product and cutting down the production cost.

He also carried on technical researches to the leak test machine waterway plugging, low pressure helium gas detection, and flexible production, which improved the equipment utilization rate and production capacity, laying a solid foundation for the company to undertake new projects.

He has always taken customers as the orientation, regarded customer satisfaction as the important standard of the work inspection, while carrying on technical improvement and tackling difficult problems unceasingly, contributing to making the company a first-class industry group.